- Home

- Products

- Electrical Inspection

- Electric Motor Predictive Maintenance

- Electric Motor Testing

- Bearing Inspection

- Condition monitoring of Rotational equipments

- Stationary Condition Monitoring with Ultrasound

- Energy Centered Maintenance

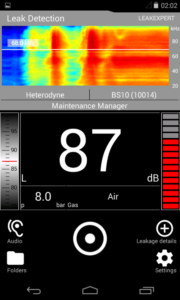

- Ultrasonic Leac Detection

- Steam Trap Testing

- Tightness Testing

- Precise Lubrication Products to improve Reliability

- Solutions & Services

- About Us

- Contact

Digiqub was founded in 2022 by a team that has managed mechanical, electrical and construction projects for many years, with the aim of supporting the digital transformation activities of industrial facilities and providing products and services.

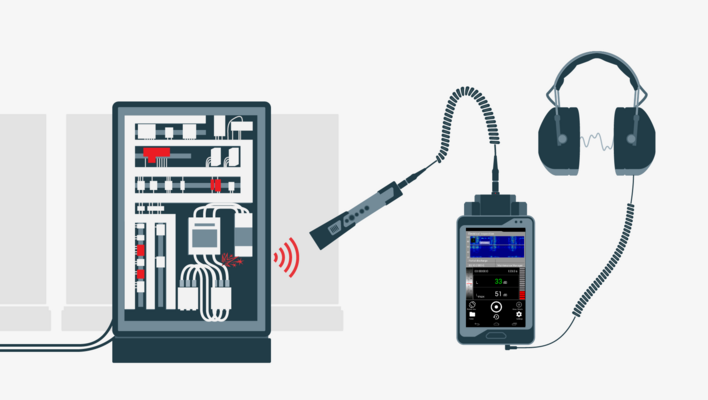

Through signal processing, ultrasound can be converted into a secondary “downmixed” signal in the audible range.

Through signal processing, ultrasound can be converted into a secondary “downmixed” signal in the audible range.