Reducing energy consumption has a lot of social and political interest as a way of achieving current energy and climate targets. With the implementation of the 2015 EU Energy Efficiency Directive at the latest, companies of a particular size and above are obligated to carry out energy audits or to become certified to standards such as DIN EN ISO 50001 and EMAS.

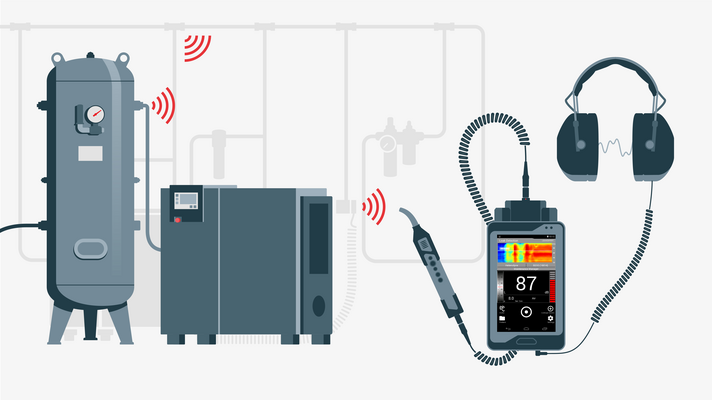

Compressed air production is an expensive process due to the low level of efficiency, and compressed air losses as a result of leaks provide a lot of potential for increasing energy efficiency. State-of-the-art broadband ultrasound testing technology is an important tool that helps companies to achieve their targets. Smartphone-based devices guide service engineers throughout the entire testing procedure: from regular leak detection and the automatic evaluation of leaks in l/min right through to documentation.

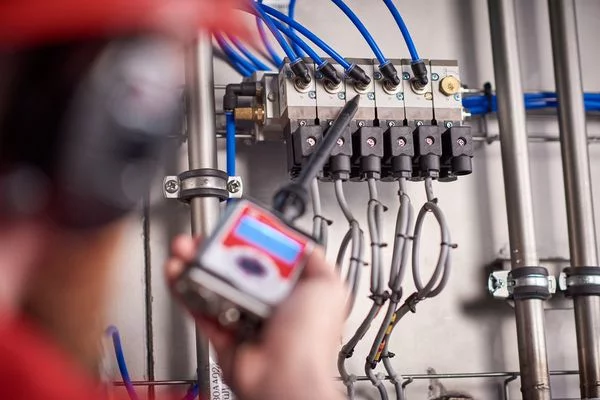

Our ultrasonic testing device SONAPHONE and our acoustic camera SONOASCREEN are used for simple and fast leak detection on compressed air, inert gas and vacuum systems. The different device versions as well as the extensive accessories offer intuitive assistance for leak detection and evaluation with ultrasound.

The process of estimating the amount of leakage in a compressed air system is part of DIN EN ISO 11011. This process provides data for energy management systems in accordance with DIN EN ISO 50001. The leakage calculator is based on the leakage loss, which were determined and classified with the SONAPHONE ultrasonic testing device with LeakExpert app. For the calculation, the compressed air index, the energy costs and the production hours must also be known.